Adopted continuous recirculation operation method with RO water distribution method

Eliminated the retained area from pretreatment portion to RO membrane to reduce the amount of endotoxin and bacteria.

ü£New long nozzle ultra-low pressure RO module adopted to prevent the contamination of raw water into the module center.

High flux (high permeable water) specification

ü£ü@Use of PVDF piping in the RO water line within the system

Adopted PVDF (polyvinylidene fluoride) which is superior to low TOC, low metal ion dissolution, interior smoothness and widely used in super pure water production line such as semiconductor, bio, pure chemical drug, restaurants, etc.

Also, by using the special welding method, we have removed the difference in level of the connection portion to significantly improve the suppression of retained bacteria.

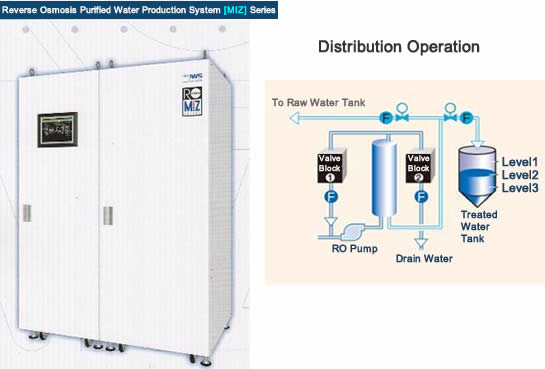

ü£ü@RO water distribution method "D Cube System"

Depending on the RO water tank level, it controls the water desalination operation (high speed/low speed), distribution operation, and stand-by operation using modulated control motorized valve.

In distribution operation and stand-by operation, the water quality on the primary side can be improved by placing the RO water back to the raw water tank.

ü£When changing to night operation, flush and replace using RO water within the module to suppress the growth of bacteria.

ü£ü@RO water can be supplied in case of emergency.

In case of RO pump malfunction, it can utilize the characteristics of super low pressure membrane to perform RO desalination operation with raw water pump through one touch operation.

ü£Equipped with automatic sterilization system after RO tank. It suppresses the secondary contamination from the water supply line.

ü£ü@Super low pressure module

Due to reduction of operating pressure, electric consumption is reduced. Furthermore, it contributes to less noise.

ü£The slow start inverter pump operation will soften the shock to the membrane and reduces the load to membrane surface.

Because it is equipped with automatic flow rate adjustment function, it can keep the water flow rate steady at all times.

ü£Adopted 10.5 inch high performance touch panel color LCD to improve operability and visibility.

Equipped with operation condition control, set value input, guidance, self diagnosis, and memory functions.

Makes system management easy by showing operating conditions graphically.

ü£In case of emergency, the operation of pretreatment bypass and RO bypass can be performed using the LCD one-touch operation.

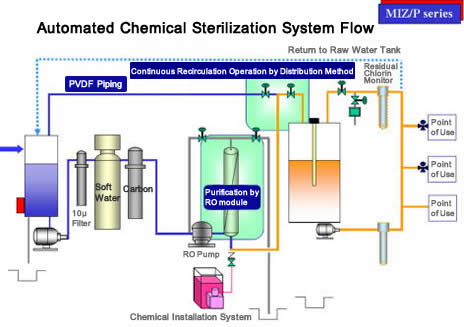

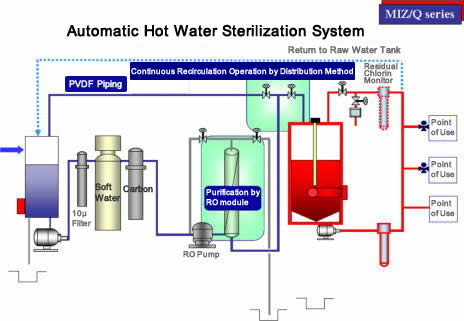

The popular MIZ series has 2 kinds of completely automatic sterilization versions.

üyMIZ/P Seriesüz

Completely automatic chemical solution sterilization system: it sterilizes from RO membrane outlet to RO tank to water supply line.

All of the sterilization processes from pouring chemical solutions, to flushing, to residual monitoring by chlorine monitor are done automatically.

Frequent and unmanned sterilization is now possible.

üyMIZ/Q Seriesüz

Completely automatic hot water sterilization system: by using the electric heater, the hot water above 80üÄ sterilizes from RO tank to water supply line.

Just like P series, all of the sterilization processes are done automatically.

| Model | TYPE-1 | TYPE-2 | TYPE-3 | TYPE-4 | ||||||||

| 252 | 253 | 254 | 255 | 256 | 257 | 258 | 751 | 752 | 753 | 754 | ||

| Maximum permeation water volume(L/h) | Heating standardüi25üÄüj/peak | 450 /550 |

680 /770 |

900 /1020 |

1200 /1250 |

1300 /1480 |

1500 /1660 |

1800 /1860 |

1100 /1250 |

2100 /2400 |

3100 /3400 |

3800 /4300 |

| Non-heating standardüi7üÄüj/peak | 230 /270 |

340 /390 |

470 /520 |

600 /640 |

650 /750 |

750 /860 |

900 /980 |

750 /810 |

1500 /1610 |

2100 /2360 |

2800 /3000 |

|

| Module (main) | 4" ESPA-FREE 3000L |

4" ESPA-FREE 3000L |

8" ESPA 3 | 8" ESPA 3 | ||||||||

| RO module (main) | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 1 | 2 | 3 | 4 | |

| Raw water temperature control | 15 | 25 | 30 | 40 | 45 | 50 | 60 | 40 | 70 | 110 | 120 | |

| Pre-filter(mmüj | 10ā╩ | 500 x 1 | 750 x 1 | 750 x 1 | 750 x 3 | |||||||

| Active coal filter(mmüj | 750 x 1 | 750 x 2 | 750 x 3 | 750 x 3 | 750 x 8 | |||||||

| Softener resin volumeüiL) | 42 | 55 | 55 | 90 | ||||||||

| Raw water tanküiL) | 95 | 110 | 110 | 260 | ||||||||

| Raw water pressurization pumpüikW) | 50/60Hz | 0.68/0.775 | 1.06/1.28 | 0.68/0.775 | 1.06/1.28 | 1.44/1.69 | ||||||

| RO pumpüikW) | Inverter | 2.2 | 2.2 | 3.6 | 3.6 | |||||||

| Water supply pumpüikW) | 50/60Hz | 0.35/0.395x 1 | 0.35/0.395x 2 | 0.35/0.395x 2 | 0.35/0.395x 2 | |||||||

| RO water tanküiL) | 180 | 260 | 260 | 300 | ||||||||

| UV bactericidal lamp(Wüj | Infiltration type | 60 | 60 | 60 | 60 | |||||||

| DimensionüiW x D x H) | 1,300x920x1,800 | 1,600x920x1,800 | 1,600x920x1,800 | 2,250x920x1,800 | ||||||||

| Product weightüikg) | 570 | 580 | 590 | 600 | 790 | 800 | 810 | 795 | 855 | 900 | 1190 | |

| Operating weightüikg) | 1060 | 1070 | 1080 | 1090 | 1400 | 1410 | 1420 | 1405 | 1485 | 1850 | 2050 | |

| Power50/60Hz (kW) | 3āėü@200V | 3.3/3.4 | 4.0/4.3 | 5.0/5.2 | 5.4/5.7 | 5.8/6.1 | ||||||

| 1āė 100V | 1.0 | 1.0 | 1.0 | 1.0 | ||||||||

| Connecting piping | Raw water inlet | 25A | 25A | 25A | 32A | |||||||

| Supply water outlet | 20A | 20Ax2 | 20Ax2 | 25Ax2 | ||||||||

| Drain water outlet | 32A | 25AüE32A | 32Ax2 | 32Ax2 | ||||||||

| Type of raw water temperature control | Electric heater method, hot water direct introduction method, boiler circulation method (separate installation), heat exchange method, heater method (separate installation) | |||||||||||

1.ü@The operating conditions of permeation water volume are 25üÄ water temperature, 0.8Mpa operating pressure, and 0.15% concentration of used raw water (NaCl).

2.ü@The time it can generate fresh water at "peak water volume" is up to 3 hours/day.

3.ü@The hardness of raw water is 55ppm as a design standard. If the value is higher than the standard, the model of the hard water softener may change.

ü@ü@At that time, there may be a change to the height of equipment. Please consult with us for details.

4.ü@The active coal filer uses 0.5ppm raw water effective chlorine as a design standard. In case it goes over the standard, the number of filters used may increase.

ü@ü@At that time, there may be a change to the equipment dimension. Please consult with us for details.

5.ü@Although the standard equipment recovery ratio is 70% at heating and 50% at non-heating, it may be lower depending on the amount of silica ion within the raw water.

ü@ü@Please consult with us for details

6.ü@For the hard water softener with chlorinator, type 1-3 are standard and type 4 is an optional spec.

ü@ü@At that time, there may be a change to the equipment dimension. Please consult with us for details.

7.ü@This specification may change without notice.